What should I do if the temperature of the injection molding machine is too high?

1. The reason for the high temperature rise of the injection molding machine

(1) The volume of the fuel tank is too small, the heat dissipation area is not enough, and the cooling device is too small in capacity.

(2) The quantitative pump oil supply system that selects the oil pump capacity according to the fast forward speed will cause most of the excess flow to overflow from the relief valve under high pressure and generate heat during operation.

(3) If the unloading circuit in the system fails or the unloading circuit is not set, the oil pump cannot be unloaded when it stops working, and the entire flow of the pump overflows under high pressure, resulting in overflow loss and heat, resulting in temperature rise.

(4) The system pipeline is too thin and too long, and the bending is too much, and the local pressure loss and the pressure loss along the process are large.

(5) The component accuracy is not enough and the assembly quality is poor, and the mechanical friction loss between relative motions is large.

(6) The fitting clearance of the fittings is too small, or the clearance is too large after use and wear, and the internal and external leakage is large, resulting in a large volume loss, such as a decrease in the volumetric efficiency of the pump and a rapid temperature rise.

(7) The working pressure of the hydraulic system is adjusted much higher than the actual need. Sometimes it is because the seal is too tight, or because the seal is damaged and the leakage increases, the pressure has to be increased to work.

(8) The temperature of the climate and operating environment is high, which causes the oil temperature to rise.

(9) The viscosity of the oil is improperly selected. If the viscosity is large, the viscous resistance will be large. If the viscosity is too small, the leakage will increase. Both conditions can cause heat generation and temperature rise.

2. Treatment method of high temperature rise of injection molding machine

(1) According to different load requirements, check and adjust the pressure of the relief valve frequently to make it just right.

(2) Reasonable selection of hydraulic oil, especially oil viscosity, when conditions permit, try to use a lower viscosity to reduce viscosity friction loss.

(3) Improve the lubricating conditions of moving parts to reduce friction loss, which is conducive to reducing workload and heat generation.

(4) Improve the assembly quality and precision of hydraulic components and hydraulic systems, strictly control the fitting clearance of fittings and improve lubrication conditions. The sealing material with small friction coefficient and the improved sealing structure are used to reduce the starting force of the hydraulic cylinder as much as possible to reduce the heat generated by the mechanical friction loss.

Main Features:

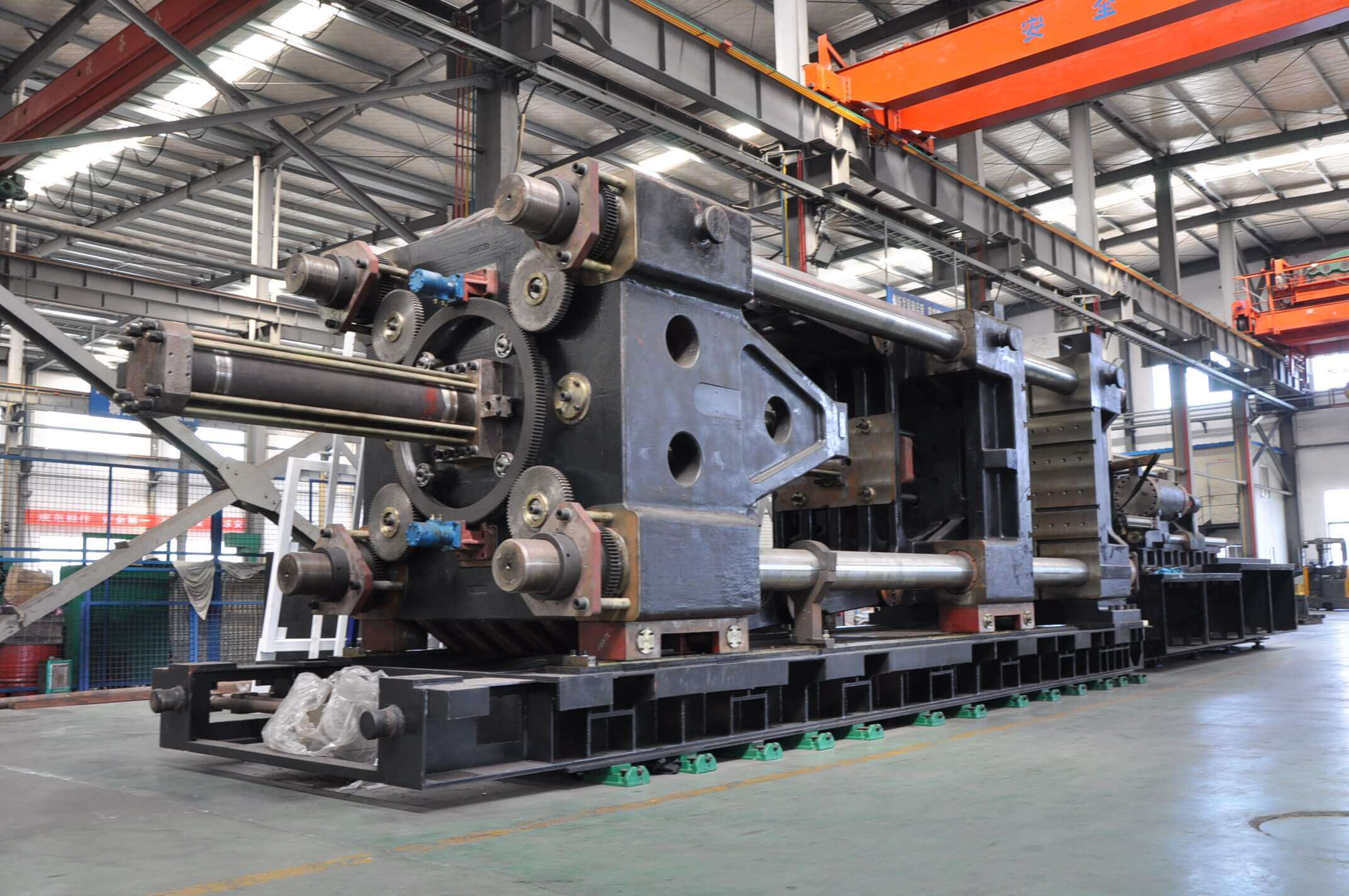

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.